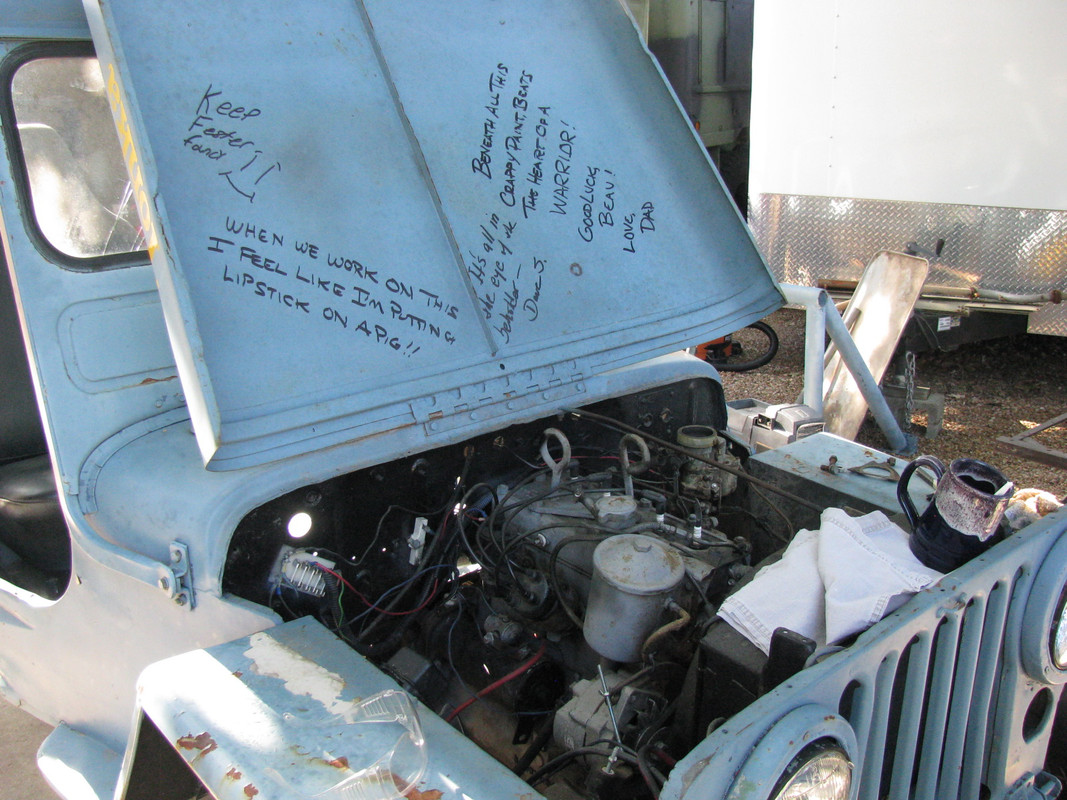

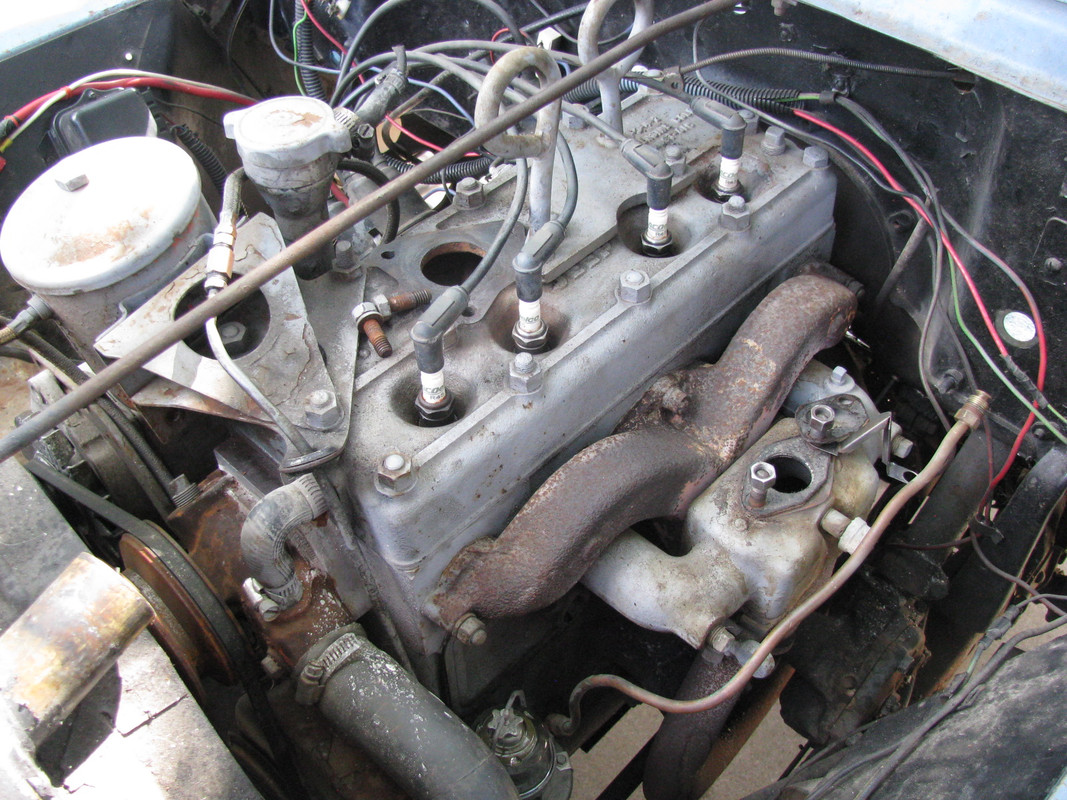

Working on this truck without a Tech Manual at the moment. As with all M-series trucks, everything in its design is fairly logical and otherwise easy to figure out but there are those little nuggets of info that only a TM can provide so we've gotta get one!

Good progress today. Removed the offending bolt which gave up with only a whimper. (All sing praises to PB Blaster!) Turned out it was only frozen up at the top of the head as I had guessed, with good threads below that.

In order to get the Vice Grip on the bolt, I removed the carburetor (which has seen better days) and discovered a puddle of fluid sitting in the intake manifold. At first, I though it might have been the MM oil but,

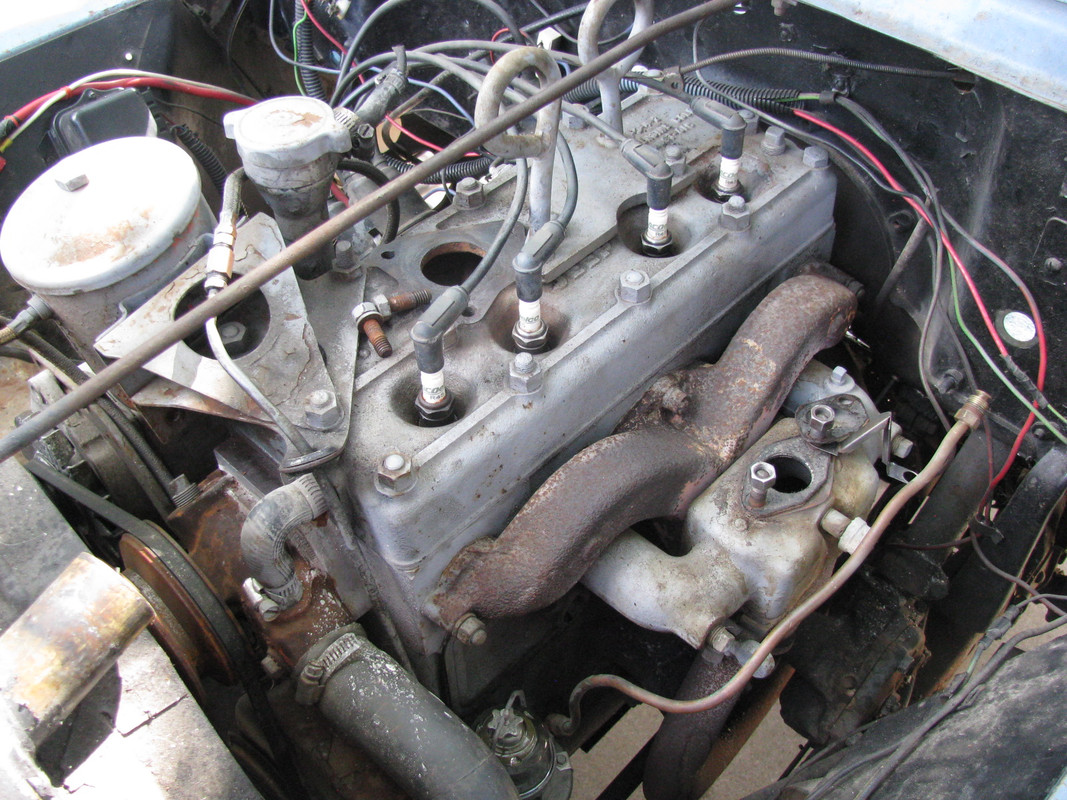

nope...it was spoiled gas. Spoiled gas is odd stuff. It has lost all its ethers, and whatever is left just doesn't want to evaporate. It hangs around for a very long time. I sopped that up with several old rags while my son did the same to the gas tank which is now perfectly clean. It may be small, it may be wrong but it is absolutely clean. Terrific. Engine is starting to look a little more businesslike.

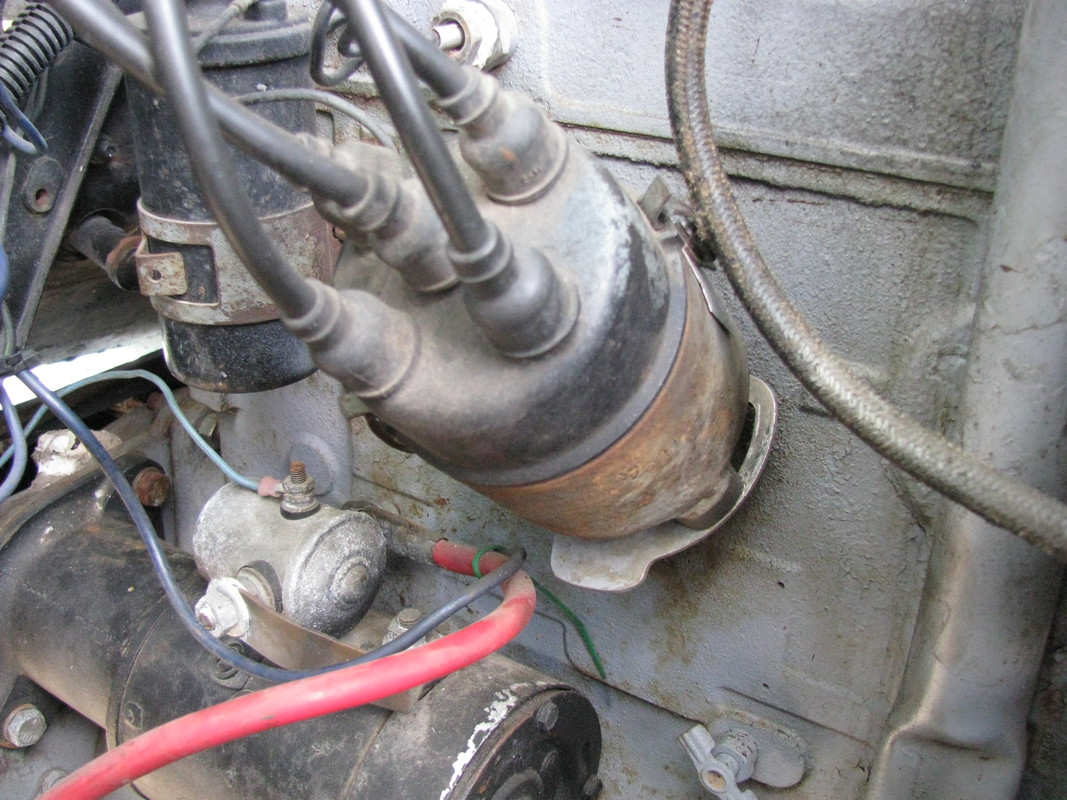

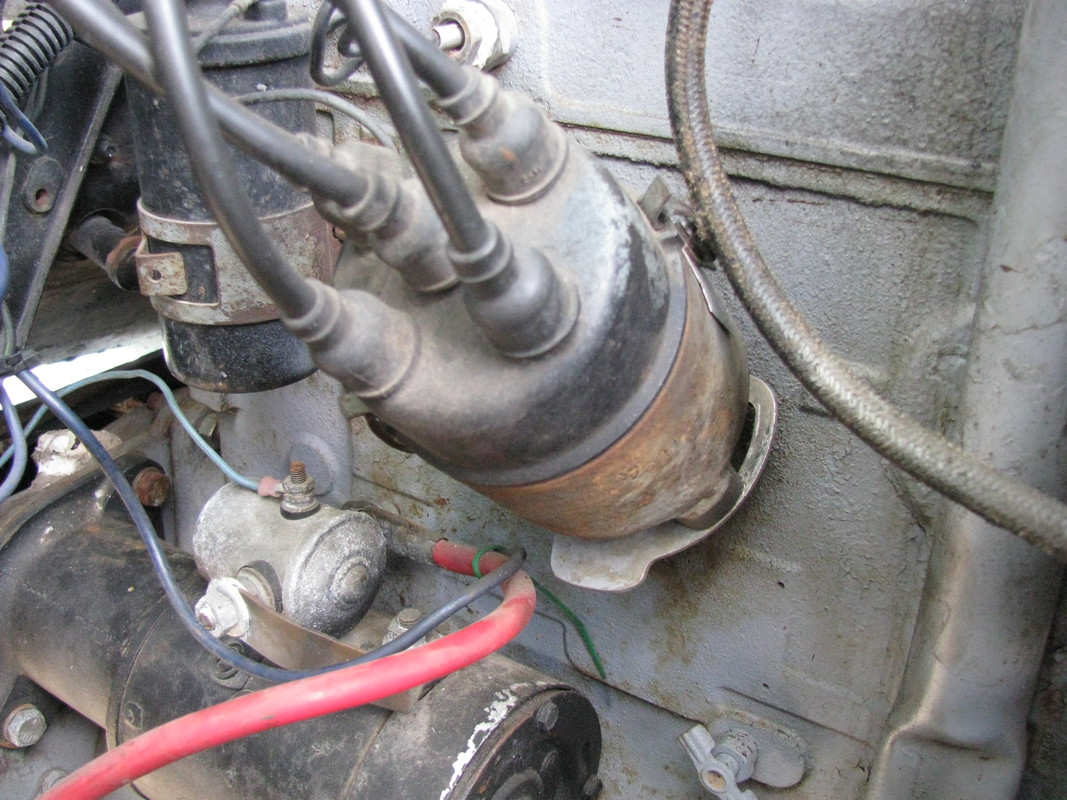

I got a large brass drift and gently tapped upon a boss on the distributor base. You can see the boss at the 4 o'clock position in the photo. The distributor grudgingly began to rotate and take a lot of paint off the surface to which the distributer locking bolt tightens. With the paint gone the distributor now rotates as it should. The points are adjusted and the park plugs are properly gapped. Getting close!

I took the thermostat housing to the blast cabinet. The neck is badly reduced in thickness owing to rust. We'll replace it but in a pinch, it could be used. The support sleeve for the thermostat has degraded into nothing more than hard, black cement-like cake. In short, this was worth the headache of the broken bolt, which, of course, is what lead me to the liquid in the intake manifold. I'm lucky like that.

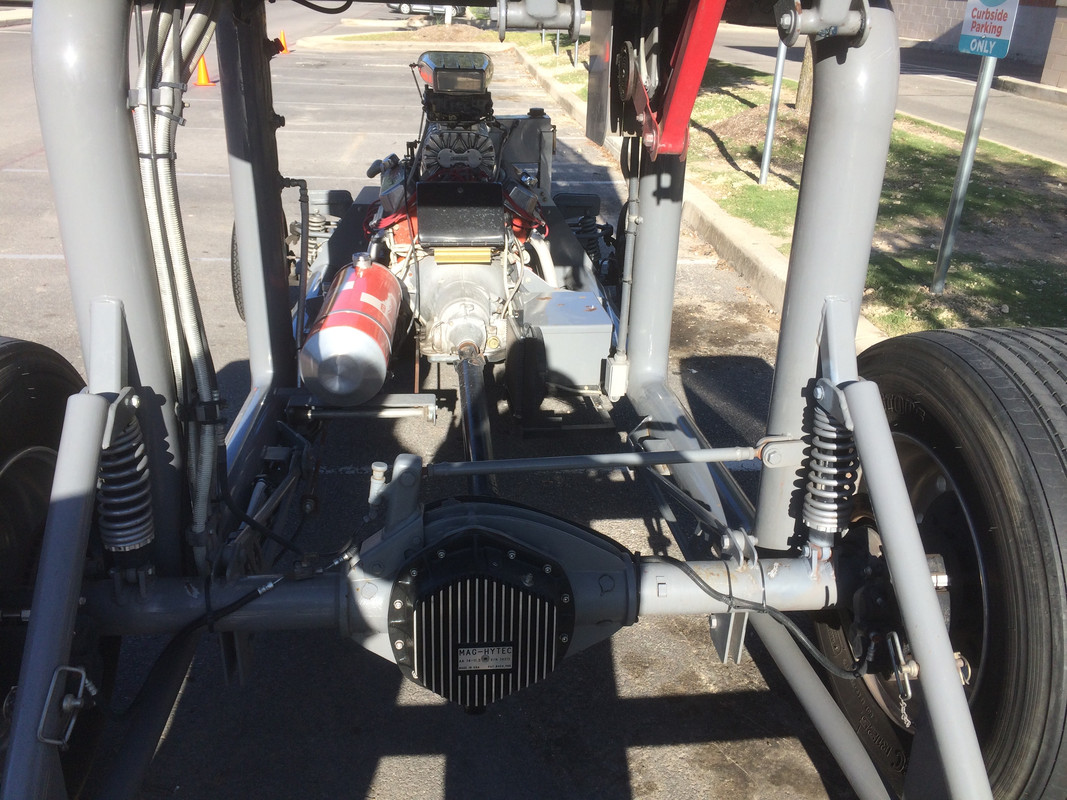

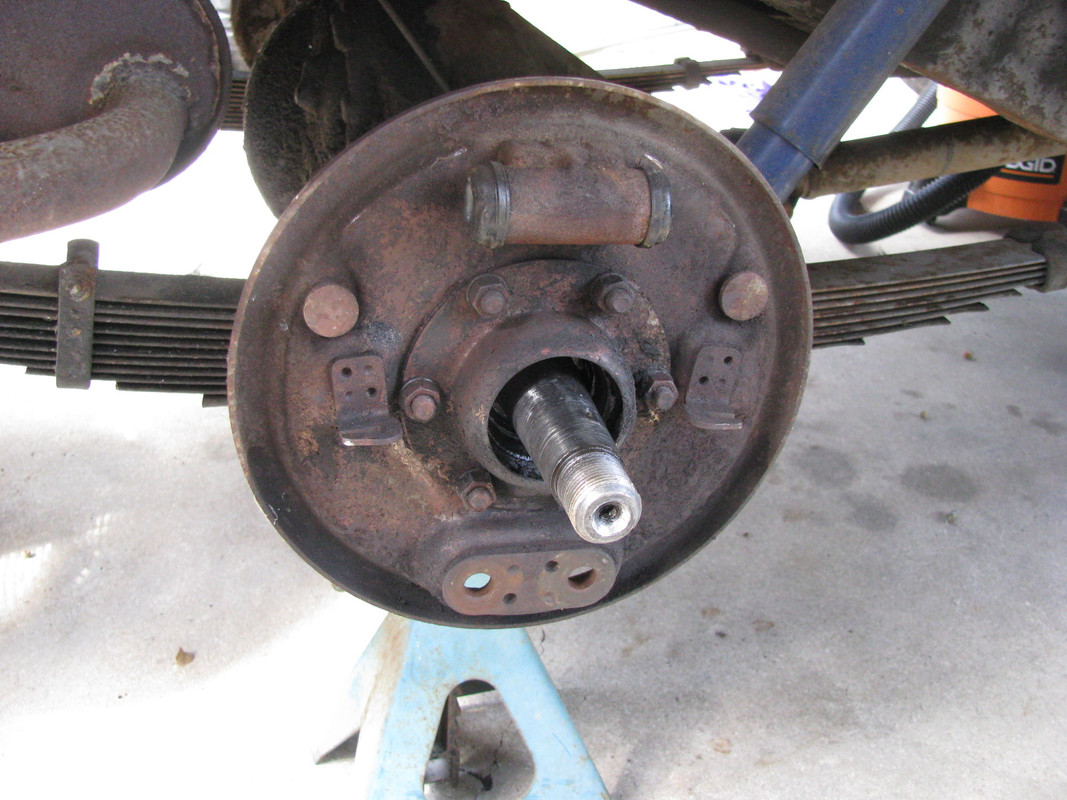

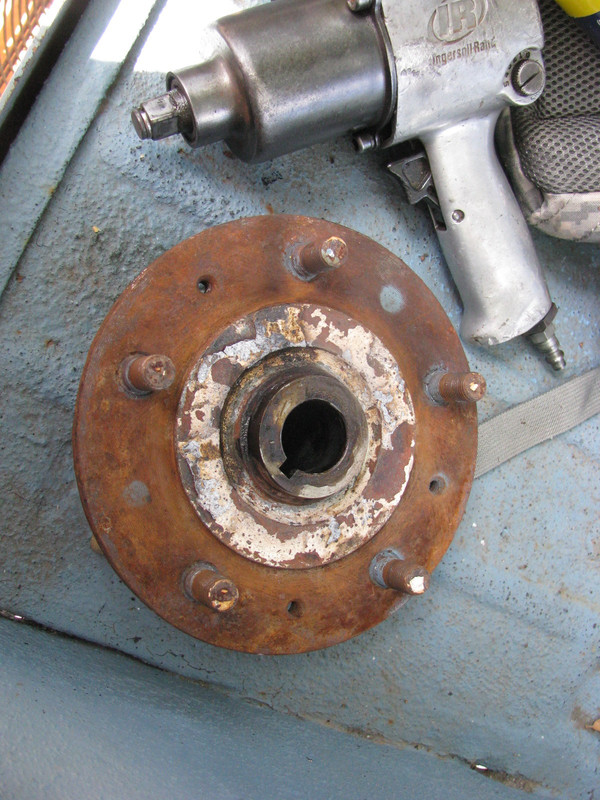

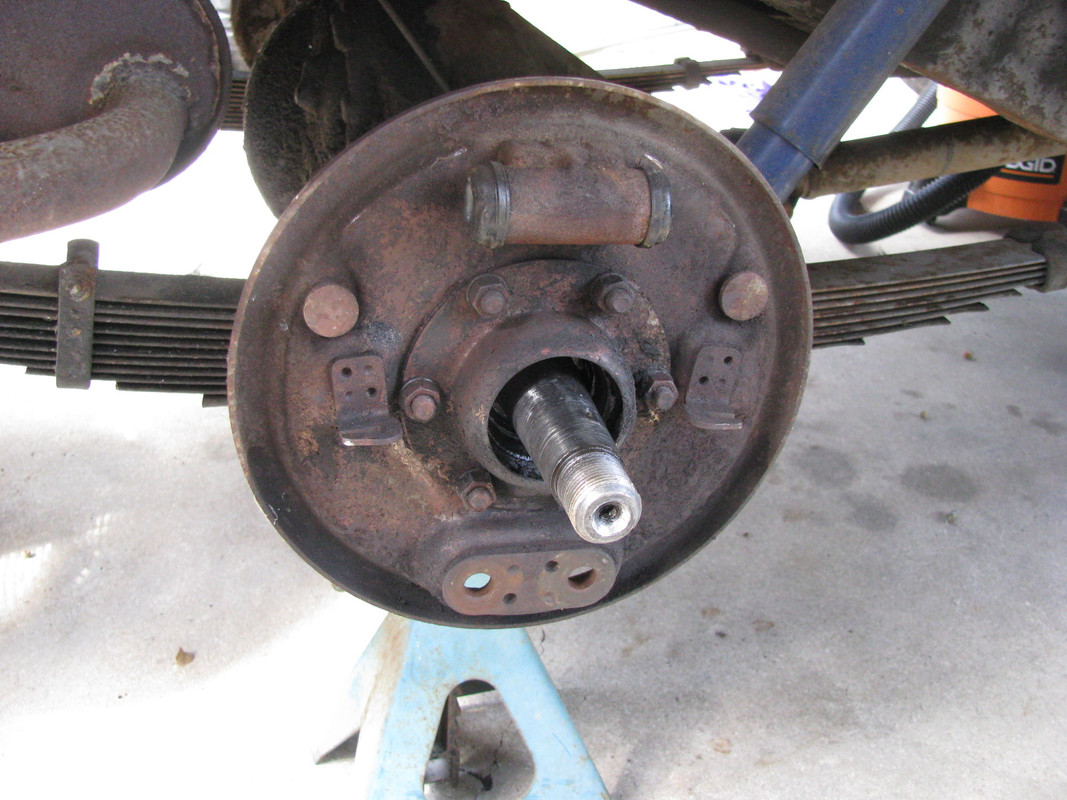

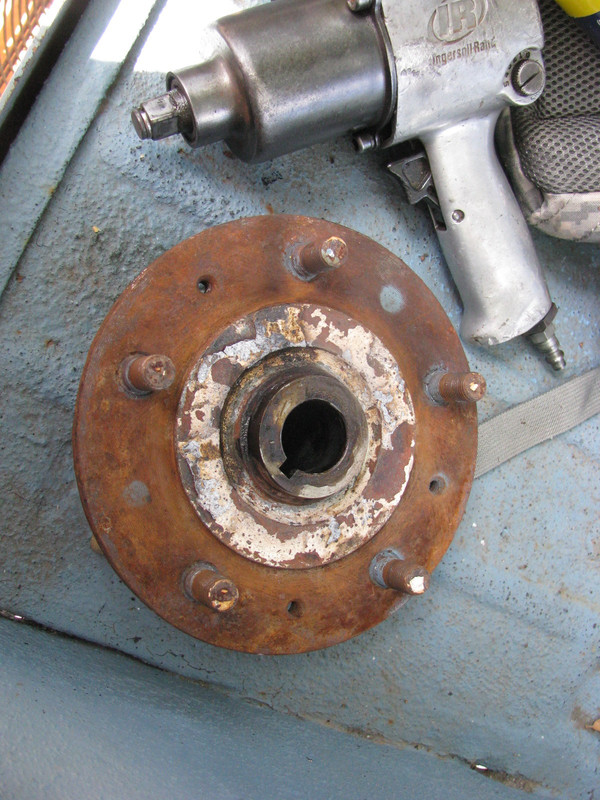

The REAL victory today came in the form of the removal of the rear axle drive flanges, which are almost perfectly fitted to a taper on the end of the axle shaft, including a long key and keyway. Removing these things was a project like no other. I ended up borrowing a huge, ancient puller that was probably designed for pulling the screws off battleships and even then, this process required the application of heat and some I've-been-workin'-on-the-railroad-style hammering. I'm not a fan of the use of hammers but in this case, I was willing to make an exception. They are off and -

TA DAH! - undamaged. Phew!

Located and removed the body ID plate, got the paint off it and set it aside for later.

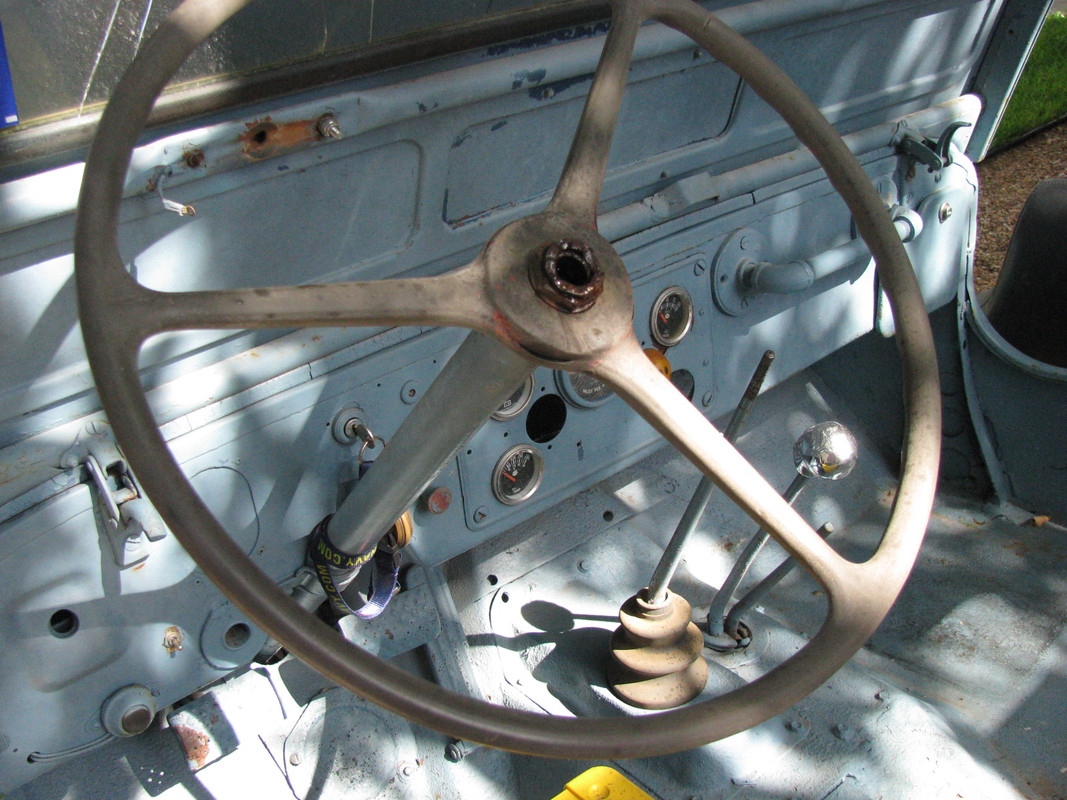

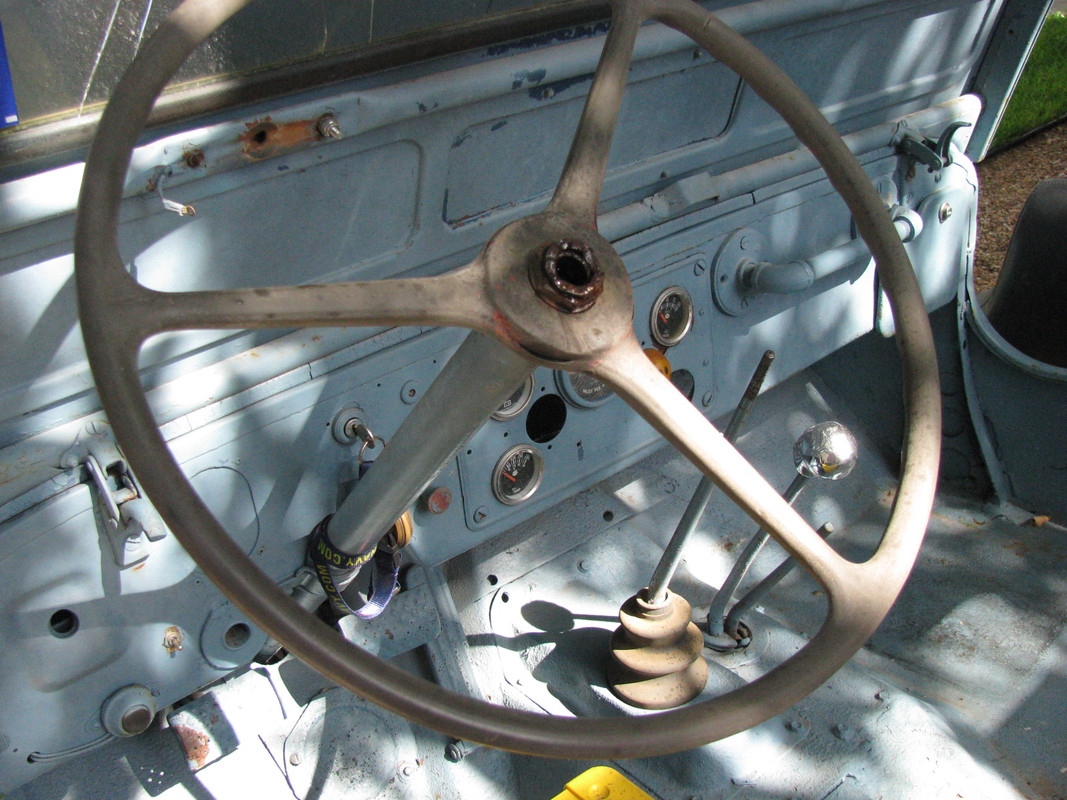

Prepping the steering wheel for removal with PB Blaster.

Tomorrow we will pull the retainer and brake backing plates off the rear axle which should expose the seal and bearings. We will clean and refinish those and their associated hardware and add new seals, bearings and whatever else is needed to the ever-growing list of the necessary parts for this truck. I already know the rear axle bearings are beyond their service life. Rotation of the axle and flange produced a pronounced feel than can only be created by flat spots worn into the bearing rollers.

On breaks I've been watching Youtube - flat-fender jeeps on the Rubicon, etc., just to stay motivated. Pretty amazing stuff. We're heading in the right direction, slowly but surely!

Cheers,

TJ